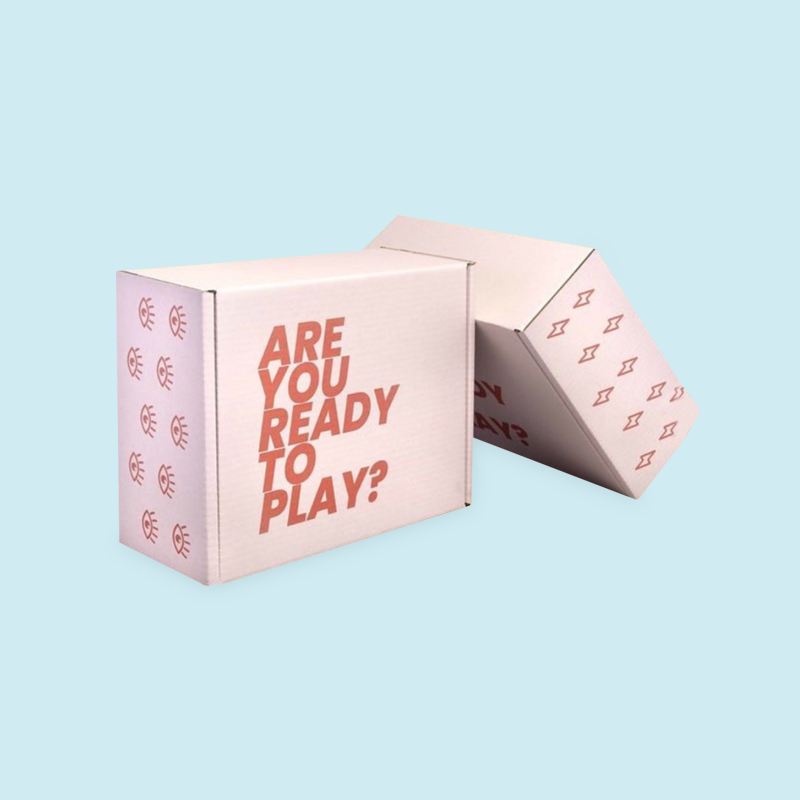

Product Overview

Corrugated packaging is made up of three or more sheets of corrugated fiberboard that is a durable, cost-effective, and versatile packaging material. Corrugated boxes are made of linerboard, which is a flat material, which is a corrugated paper attached between the linerboard.

Get Free Quotation